|

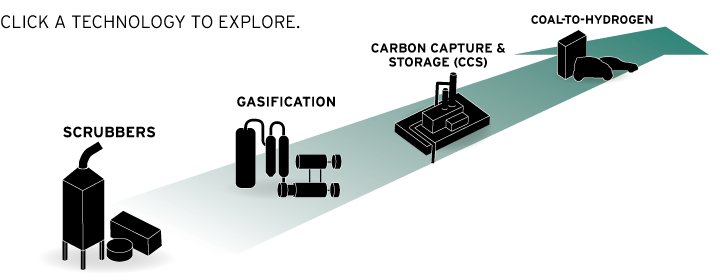

Coal is a cheap, abundant and secure source of power generation. It is also one of the most polluting fossil fuels. Some existing and developing technologies that build on one another could contribute to the likelihood of producing and burning “cleaner coal” in the future. Four are described below: |

|||

|

|||

|

BY THE NUMBERS |

|||

| 25% | Increase in projected power generation from coal between 2009 and 2035 | 230% | Increase in clean energy investments between 2005 and 2009 globally |

| 30 | Number of states with some form of renewable or clean energy mandate in their power sectors | 75% | Increase in the cost of electricity from coal plants with commercially available CCS technologies |

| $3.4 billion | Funds allocated for development of clean coal technologies to the Office of Fossil Energy from the Recovery Act of 2009 | $7 billion | Estimated private investment in CCS technologies in the U.S. in the next decade |

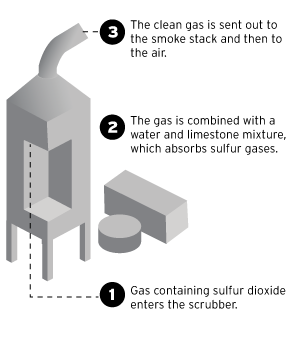

SCRUBBERS |

|||

Technical name: “flue-gas desulfurization units.” Commonly called “scrubbers” because they “scrub” sulfur out of the smoke released by coal-burning boilers.WHY?Scrubbers can reduce sulfur emissions from burning coal by 90 percent or more. In certain coal plants, scrubbers can also help reduce mercury emissions, an added value that is still being further developed by scientists. WHEN?In the U.S., 110 coal-fired power plants already use more than 190 scrubbers. All coal-fired plants built after 1978 are required to have special devices, such as scrubbers, to reduce the sulfur released with coal combustion. CHALLENGESThe U.S. is now debating legislation that would regulate toxic emissions from old and new power plants through the Environmental Protection Agency. Scrubbers would be the most optimal technology for electricity plants to meet these requirements. The regulation has become controversial; the coal industry and some political groups oppose it. Critics argue that the costs associated with scrubbers will prompt the closure of power plants, especially smaller ones, with negative implications for the U.S. labor market. In contrast, the Environmental Protection Agency argues that the increased use of scrubbers in power plants would result in job growth in the construction sector. COSTSScrubbers cost between $100 million and $200 million per power plant. Up to half of the cost of a power plant can go to pollution-control equipment. |

|

||

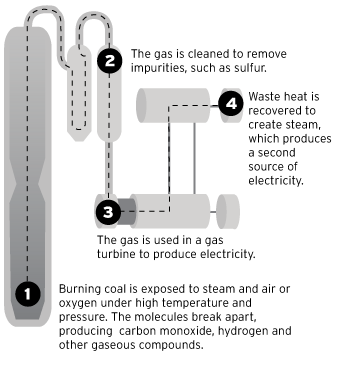

GASIFICATION |

|||

Integrated Gasification Combined Cycle (IGCC)WHY?This technology improves burning efficiency while reducing emissions. Gasification is one of the cleanest ways to convert coal into electricity or hydrogen. Burning coal can be turned into a gas that can be cleaned of more than 99 percent of its sulfur and nitrogen impurities. Coal gasification processes under development by the Energy Department could cut the formation of carbon dioxide by more than 40 percent compared to a conventional coal-burning plant. According to the National Energy Technology Laboratory, IGCC power plants also generate more electricity from a given amount of coal. Conventional power plants extract 33 to 35 percent of the energy value of coal, whereas gasification plants can extract 60 percent of coal’s energy. WHEN?Medium-term future. Coal gasification electric power plants are already operating commercially in the U.S., but in small numbers compared to conventional power plants. A gasification project in Mississippi will be the world’s first large-scale carbon capture and storage project in the power sector that also integrates gasification. CHALLENGESCoal-gasification plants are more expensive than conventional coal-fired plants, a challenge to becoming commercially viable. An increase in the costs of electricity from more expensive plants could create political opposition because, according to energy experts, politicians have not been willing to pass any environmental regulations that would increase retail power prices by more than a few tenths of a cent per kilowatt-hour. COSTSFew such plants operate today, so it’s difficult to estimate how expensive they would be if they become widely commercial. But experts estimate that implementing gasification technology could add two to three cents per kilowatt-hour to the retail price of electricity. That increase in electricity prices would be significant because the current price of a kilowatt-hour of electricity in the United States is 11.3 cents. |

|

||

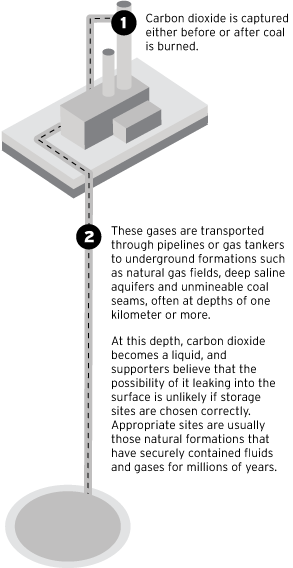

CCS |

|||

Carbon Capture and Storage technology, commonly known as CCSWHY?CCS reduces pollution by allowing carbon dioxide from coal plants to be stored underground in conjunction with gasification plants. Carbon dioxide is the main gas associated with global climate change. According to the International Energy Agency, CCS could result in a 19 percent reduction of energy-related emissions to the atmosphere by 2050 if 3,000 CCS projects are put into place during the next four decades. WHEN?Long-term future. Carbon capture has been used in the natural gas and chemical industries for almost 40 years in the U.S., but CCS technologies are still considered immature in the power industry. The technologies needed to implement CCS for coal in the U.S. already exist but have not been produced together at commercial scale. Four commercial CCS facilities operate globally in the coal industry. The U.S. Department of Energy funds demonstration projects with almost $4 billion in federal money, as well as tax credits and loan guarantees. Another $7 billion in private investments has been committed to these efforts. To ensure that carbon can be stored safely for centuries, commercial CCS still requires refinements in the ability to measure, monitor and verify that the gases injected into underground formations have not leaked. The use of deep saline formations for storage is fairly new and has been tested in only a few projects. The U.S. government’s goal is to integrate current CCS technologies with commercial-scale power plants to prove that they can operate efficiently. The demonstration phase will likely last for another decade. Other experts are less optimistic about the time frame, estimating that no more than 12 commercial CCS plants will be built by 2020 worldwide. According to these estimates, even with funds invested and more technology adoption, by 2030 “clean coal” processes might account for only 3 to 5 percent of the infrastructure that uses coal. CHALLENGESThe key challenge to implementing CCS is cost. Because the value of the technology lies in reducing carbon dioxide emissions alone, existing power plants do not have an economic incentive to implement this technology. Its adoption will depend on the government’s ability to push for environmental policies that would address carbon dioxide emissions such as carbon pricing, technology mandates or subsidies to make it commercially attractive. Moving CCS forward will likely depend on reaching a consensus among political leaders on the need to cut carbon dioxide emissions and then by how much. Another challenge is the long-term liability and property rights of geologic storage sites. In the United States where mineral rights are privately owned, securing property rights for underground areas will be a novel legal issue. If certain states do not allow underground carbon dioxide storage, it would have to be transported to other states through a new network of pipelines. Long-term liability is considered one of the most challenging issues associated with regulation of carbon dioxide storage activities and determining who would be responsible for any potential environmental accidents, such as carbon dioxide leakages. COSTSThe Department of Energy estimates that current CCS technologies could increase the cost of electricity by 75 percent in traditional coal plants and 35 percent for an advanced gasification-based plant. The Global CCS Institute estimates that CCS adoption could increase production costs by some 40 to 76 percent. In some countries, power plants can reduce the cost of cutting emissions through cap-and-trade markets. Each plant is issued a number of permits for carbon dioxide emissions. If it maintains emissions below the number of permits, it can sell or trade the difference to a plant that emits more into the air than it can cover with its permits. Industry experts estimate that CCS technologies could be economically viable if a plant had to pay $50 to $100 per ton of carbon dioxide in cap-and-trade markets. But recently, the prices of carbon dioxide in cap-and-trade markets have dropped to as low as $15 per ton because of low industrial productivity during the economic recession. |

| ||

COAL-TO-HYDROGEN |

|||

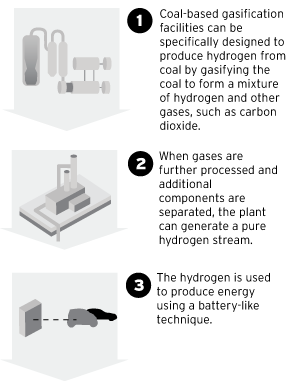

A hydrogen-based energy system using coal resources.WHY?Hydrogen, like electricity, can carry and store energy produced from resources such as coal. In this capacity, it can be used for power generation and to run automobiles. Hydrogen systems could be built around CCS and gasification processes. Hydrogen fuel cells themselves emit virtually no pollution or greenhouse gases. Because most of the projected growth in carbon dioxide emissions in the future would come from the electricity generation and transportation sectors, the use of hydrogen could address climate change concerns.

Additionally, it could help reduce U.S. dependence on foreign oil. WHEN?Long-long-term future. Hydrogen could be produced using gasification plants. But no commercial demonstrations of these joint power and hydrogen plants were in operation by mid-2011. Computer-based conceptual plants have been simulated to estimate the technical and economic performance of co-production facilities. The U.S. government’s Hydrogen and Clean Coal Fuels Program investigates innovative technologies and methods to produce, deliver and utilize hydrogen from coal. CHALLENGESThe commercialization of hydrogen as a reliable and cost-effective fuel is still in early stages. Substantial research and development are required and have focused on advanced water-gas shift technologies, hydrogen separation, process intensification and project demonstrations. COSTSThe cost of a coal-to-hydrogen plant with carbon storage would be more than $350 million. |

|

||

CREDITS

Reporting by Hely Olivares

Graphics by Kristen Long

SOURCES

U.S. Energy Information Administration- Annual Energy Outlook 2011

The Hamilton Project- Promoting Clean Energy in the American Power Sector- Joseph E. Aldy (PDF)

The Pew Environment Group- Who’s Winning the Clean energy race? (PDF)

National Energy Technology Laboratory

Global CCS Institute

The Pew Environment Group- The Global Clean Energy Economy at a Glance

U.S. Environmental Protection Agency- CONTROLLING SO2 EMISSIONS: A REVIEW OF TECHNOLOGIES- Ravi K. Srivastava (PDF)

Boston Review- Living with coal: Climate policy’s most inconvenient truth-David G. Victor and Richard K. Morse